1. Precision Fabrication as the Backbone of Heavy Machinery Performance

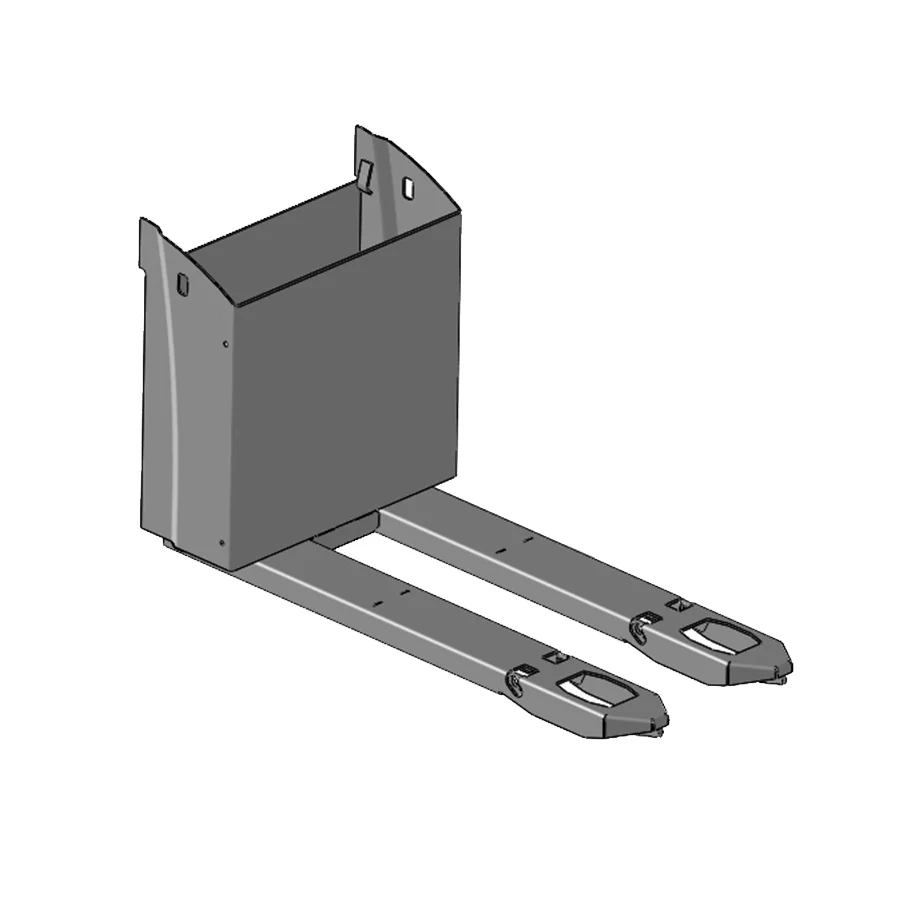

In heavy-duty equipment such as loaders, tractors, and forklifts, the fork plays a vital role in handling, lifting, and stabilizing materials. A single defect in fork design or fabrication can lead to operational inefficiency, premature wear, or even safety hazards. That’s why high-precision fork fabrication has become a critical focus in the construction and agricultural machinery industries — where performance, durability, and reliability define competitiveness.

Fork fabrication isn’t simply about shaping metal; it’s a fusion of engineering design, material science, and manufacturing precision. A well-fabricated fork must maintain perfect geometry, load balance, and structural integrity, even under dynamic and uneven loading conditions.

This comprehensive guide explores how Hengli, a leading Chinese manufacturer integrating the entire metal supply chain, delivers world-class fork fabrication solutions that power global OEMs across machinery sectors.

2. Understanding the Technical Demands of Fork Fabrication

Forks operate in highly demanding environments — exposed to heavy loads, vibrations, and abrasive materials. Therefore, every stage of the manufacturing process must be engineered for performance consistency.

Key technical demands include:

-

High mechanical strength to endure constant lifting and bending.

-

Excellent fatigue resistance for long service life.

-

Dimensional precision to ensure perfect fit with other assemblies.

-

Corrosion protection for outdoor exposure and variable weather conditions.

-

Repeatable manufacturing quality to meet OEM mass production requirements.

Meeting these standards requires not only advanced machinery but also deep process control and manufacturing discipline — areas where Hengli’s automated and digitalized production systems excel.

3. The Material Foundation: Selecting the Right Steel

The performance of a fork begins with its material. Different working conditions demand tailored steel grades that balance strength, ductility, and weldability.

Hengli’s material engineers select from a range of high-strength carbon steels, alloy steels, and microalloyed steels based on the intended application:

-

Q345 / S355 series: General-purpose structural steel, ideal for mid-range machinery.

-

42CrMo / SCM440: High-toughness alloy steel for heavy-duty forks.

-

Wear-resistant steel (Hardox / NM400): For abrasive or high-impact working conditions.

Each batch of raw material undergoes spectral analysis, hardness verification, and mechanical testing to ensure compliance with ISO and GB standards before entering the production line.

This rigorous approach ensures that every Hengli-fabricated fork achieves optimal yield strength, hardness, and elongation properties — critical to resisting deformation under extreme conditions.

4. Step-by-Step Overview of Hengli’s Fork Fabrication Process

4.1 Precision Cutting

The journey begins with CNC laser, plasma, or flame cutting, chosen based on material thickness and tolerance requirements.

-

Laser cutting: Used for high-precision, thin-plate components.

-

Plasma cutting: Ideal for medium-gauge materials with consistent edge quality.

-

Flame cutting: Applied to thick structural plates exceeding 30mm.

Hengli’s automated nesting software optimizes material usage and minimizes scrap, contributing to both cost efficiency and sustainability.

4.2 Bending and Forming

Forming determines the fork’s geometry and load distribution. Hengli employs CNC-controlled press brakes and hydraulic forming systems to maintain consistent curvature and angle accuracy.

Every forming process is digitally monitored to prevent spring-back or cracking, ensuring long-term structural performance without distortion.

4.3 Machining and Hole Processing

Fork interfaces — such as mounting holes, pivot points, and welded joints — require extremely tight tolerances.

Using multi-axis CNC machining centers, Hengli achieves precision down to ±0.02 mm, ensuring perfect compatibility with the customer’s assembly design.

This precision directly translates to reduced vibration, less assembly time, and greater mechanical stability in the final machine.

4.4 Robotic Welding and Assembly

Welding defines the fork’s strength and fatigue life. Hengli combines robotic MIG/MAG welding stations with manual TIG finishing for high-stress joints.

Robotic systems guarantee:

-

Uniform penetration depth.

-

Consistent bead geometry.

-

Reduced thermal deformation.

Hengli’s welding engineers program each robot cell using 3D models and real-time sensors, maintaining perfect consistency even across large production batches.

For specialized components or prototypes, manual welders certified to AWS D1.1 and ISO 9606 handle fine-tuning and final inspection.

4.5 Surface Treatment and Coating

Durability isn’t just about structure — it’s also about protection. Forks used in agriculture and construction face exposure to moisture, chemicals, and abrasive soil.

Hengli provides a full range of finishing options:

-

Powder coating: Durable, environmentally friendly coating for corrosion resistance.

-

Hot-dip galvanizing: Ideal for outdoor or coastal conditions.

-

Electrostatic painting: Smooth, aesthetic finish for high-visibility machinery.

Each coating process follows strict thickness and adhesion testing to meet customer specifications and ensure lasting performance.

4.6 Final Inspection and Quality Assurance

Every fork assembly passes through a multi-layered inspection regime:

-

Dimensional Verification: Using CMM (Coordinate Measuring Machines).

-

Non-destructive Testing (NDT): Ultrasonic and magnetic particle inspection for internal flaws.

-

Load Simulation: Structural performance testing under real-world stress conditions.

-

Surface Quality Check: Visual and thickness tests for coating consistency.

By combining digital inspection with operator expertise, Hengli ensures zero defect delivery for both small-batch prototypes and large-scale OEM production.

5. Automation, Smart Manufacturing, and Digital Integration

As industrial production transitions toward Industry 4.0, Hengli has built a smart factory system that integrates data, robotics, and AI-assisted control.

Key smart manufacturing features include:

-

MES (Manufacturing Execution System): Real-time production tracking and scheduling.

-

Robotic Welding Lines: Automated operation and real-time seam quality monitoring.

-

Digital Tool Management: Intelligent toolpath optimization in CNC machining.

-

IoT Equipment Monitoring: Predictive maintenance to minimize downtime.

This intelligent system enables Hengli to achieve shorter lead times, lower defect rates, and cost-effective customization — perfectly suited for global OEM clients.

6. Customization and Engineering Support for OEM Partners

Every OEM customer has unique design goals — from lightweight attachments to heavy-lift systems. Hengli’s engineering and R&D team collaborates directly with clients to tailor:

-

Material grade and plate thickness.

-

Structural reinforcement design.

-

Weld joint optimization.

-

Coating type and visual branding.

With advanced CAD/CAM integration, Hengli can simulate fabrication outcomes before production, reducing prototyping cycles and enabling faster go-to-market timelines.

This one-stop solution allows customers to outsource complex fabrication while maintaining complete design control and confidentiality.

7. Applications Across Key Sectors

Hengli’s fork fabrication capabilities serve a diverse range of applications:

| Industry | Typical Applications | Key Requirements |

|---|---|---|

| Construction Machinery | Loader forks, excavator attachments | High strength, fatigue resistance |

| Agricultural Machinery | Tractor forks, harvesting attachments | Corrosion resistance, balance |

| Material Handling & Logistics | Forklift tines, pallet forks | Precision alignment, surface hardness |

| Energy & Mining | Handling arms, lifting brackets | Impact resistance, heat treatment stability |

Through years of collaboration with global equipment manufacturers, Hengli has established reputation and reliability in each of these sectors, providing both standardized products and custom-engineered solutions.

8. Quality Control and International Standards

Quality assurance at Hengli extends beyond inspection — it’s built into every process step.

Hengli’s operations are certified under ISO 9001, ISO 3834 (Welding Quality), and ISO 14001 (Environmental Management), ensuring compliance with international manufacturing standards.

Each project follows a documented quality plan covering:

-

Material certification traceability.

-

Process validation and in-process monitoring.

-

Final inspection reports and customer-specific testing protocols.

This approach delivers repeatable global quality, making Hengli a trusted supplier to top-tier machinery OEMs across Asia, Europe, and North America.

9. Sustainability and Environmental Commitment

In modern fabrication, sustainability is no longer optional. Hengli actively integrates eco-efficient technologies to minimize environmental impact:

-

Laser cutting optimization software reduces material waste by up to 15%.

-

Powder coating systems utilize solvent-free, recyclable materials.

-

Energy-efficient CNC machines reduce power consumption per cycle.

-

Closed-loop water systems eliminate process wastewater discharge.

These initiatives align with global OEM sustainability goals and enhance Hengli’s position as a green manufacturing partner.

10. The Future of Fork Fabrication: Toward Digital Precision and Global Integration

As machinery design becomes increasingly data-driven, the future of fork fabrication lies in digital twin modeling, AI-assisted process optimization, and smart robotics.

Hengli is already moving toward this future — integrating real-time digital monitoring, predictive analytics, and automated quality feedback loops across its production ecosystem.

By combining engineering precision with data intelligence, Hengli aims to redefine global standards for heavy-duty component manufacturing — ensuring customers benefit from both innovation and long-term stability.

11. Why Leading OEMs Choose Hengli

-

Full-chain integration: From steel procurement to finished assembly.

-

Advanced equipment: Laser cutting, robotic welding, CNC machining.

-

High efficiency: Smart scheduling for reduced delivery time.

-

Custom engineering: Tailored solutions for each client’s application.

-

Global reliability: Export experience across multiple industries.

Hengli doesn’t just fabricate forks — it delivers complete manufacturing partnerships built on precision, efficiency, and trust.

12. Conclusion: Building the Future of Heavy Equipment Manufacturing

High-precision fork fabrication represents the perfect intersection of engineering excellence and manufacturing innovation.

Through its fully integrated production system, Hengli ensures that every fork — whether for construction, agriculture, or special vehicles — meets the highest standards of performance, safety, and durability.

As industries move toward automation and sustainability, Hengli continues to lead the way with smart, efficient, and globally competitive fabrication solutions.

Call to Action

Looking for a reliable partner for custom fork fabrication and heavy equipment component manufacturing?

Partner with Hengli — your trusted expert in precision metal processing and intelligent manufacturing solutions.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.