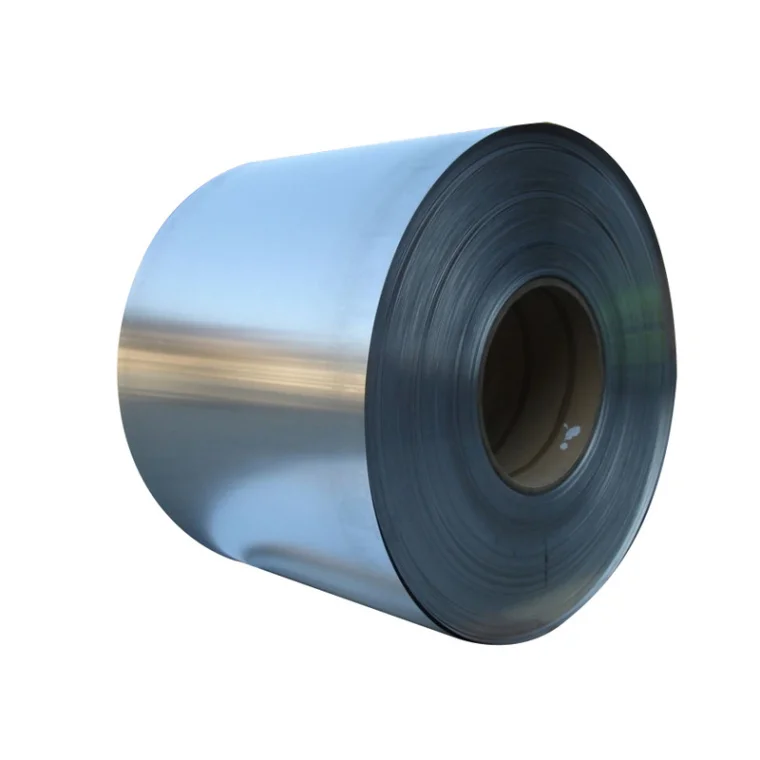

Aluminum coils are one of the most versatile and widely used metal products in modern industry. Rolled into long, continuous sheets or strips, aluminum coils offer a combination of lightweight strength, corrosion resistance, and excellent thermal and electrical conductivity. These properties make them indispensable across multiple sectors, including construction, manufacturing, packaging, and transportation. Companies like Fuchuan Metal Co., Ltd. specialize in producing high-quality aluminum coils, alongside stainless steel, high-temperature alloys, nickel-based alloys, and copper products, serving industries ranging from chemical processing to aerospace.

What Is an Aluminum Coil?

An aluminum coil is essentially a rolled aluminum sheet wound into a coil for easy transport, storage, and fabrication. Aluminum coils can vary in thickness, width, and alloy composition to meet specific industrial needs. Depending on the intended application, the aluminum may be:

-

Hot-rolled, which offers increased strength and ductility for construction and heavy-duty manufacturing.

-

Cold-rolled, which provides a smooth finish and precise thickness for automotive, packaging, and consumer product applications.

The flexibility of aluminum coils allows manufacturers to cut, shape, and process the material into finished products efficiently, reducing material waste and labor costs.

Key Properties of Aluminum Coils

Aluminum coils are highly valued in modern industries due to their unique properties:

-

Lightweight and Strong: Aluminum is approximately one-third the weight of steel while maintaining good structural strength.

-

Corrosion Resistance: Aluminum naturally forms an oxide layer that protects it from corrosion, making it suitable for outdoor and harsh environments.

-

Excellent Conductivity: Aluminum conducts heat and electricity efficiently, making it ideal for heat exchangers, electrical components, and HVAC systems.

-

Recyclable and Sustainable: Aluminum can be recycled without losing its quality, supporting green manufacturing and sustainable development goals.

Industrial Applications of Aluminum Coils

Aluminum coils are used extensively across a wide range of industries, including:

1. Construction and Architecture

Aluminum coils are used for roofing, siding, curtain walls, and decorative panels due to their corrosion resistance, lightweight nature, and aesthetic appeal. Architects often choose aluminum for its flexibility in design and ability to withstand extreme weather conditions.

2. Manufacturing and Machinery

In manufacturing, aluminum coils are fabricated into machine components, casings, and structural parts. Fuchuan Metal Co., Ltd. supplies high-quality aluminum coils for industries such as chemical processing, petroleum, synthetic fiber production, and paper manufacturing.

3. Transportation and Automotive

Aluminum’s lightweight and durability make it ideal for automotive and aerospace applications. Coils are processed into panels, body parts, and interior components, helping reduce vehicle weight, improve fuel efficiency, and enhance safety.

4. Food and Packaging Industry

Aluminum coils are used in foil production, beverage cans, and packaging materials due to their non-toxic properties, corrosion resistance, and ability to preserve food quality.

5. Energy and Utilities

Aluminum’s excellent thermal conductivity makes it ideal for heat exchangers, boilers, and HVAC systems. Coils are also used in nuclear power plants, natural gas facilities, and other energy applications requiring reliable thermal and electrical performance.

6. Aerospace and Defense

High-performance aluminum alloys processed from coils are critical in aerospace and defense applications. Lightweight, corrosion-resistant, and strong, these materials are used in aircraft structures, shipbuilding, and specialized machinery.

Why Choose High-Quality Aluminum Coils

Choosing high-quality aluminum coils ensures:

-

Consistency in thickness and mechanical properties for precise fabrication

-

Enhanced corrosion resistance and durability for long-term applications

-

Compatibility with downstream processing such as cutting, forming, and coating

Fuchuan Metal Co., Ltd. is a trusted provider of aluminum coils, offering reliable supply chains and products that meet international quality standards. Their aluminum coils are widely used in chemical, petroleum, aerospace, shipbuilding, food machinery, environmental protection, and construction industries.

Conclusion

Aluminum coils are a cornerstone of modern industrial manufacturing, offering lightweight strength, corrosion resistance, and adaptability for numerous applications. From construction and automotive to aerospace and food packaging, aluminum coils play a vital role in improving efficiency, durability, and sustainability. Partnering with experienced manufacturers like Fuchuan Metal Co., Ltd. ensures access to high-quality aluminum coils that meet industry-specific requirements, helping businesses achieve reliable performance and long-term success in their operations.

www.fuchuansteel.com

Fuchuan Metal Co., Ltd.