In the world of industrial packaging, efficiency, protection, and sustainability are key. One material that is rapidly transforming the way goods are secured and shipped is stretch hood film. Widely adopted in industries ranging from construction materials to chemicals and food & beverage, this advanced packaging solution is redefining pallet load protection.

In this article, we’ll break down what stretch hood film is, why it’s becoming the preferred choice in automated packaging lines, and how companies like Dostar Packing Equipment Co., Ltd are leading the way with integrated stretch hood solutions.

What Is Stretch Hood Film?

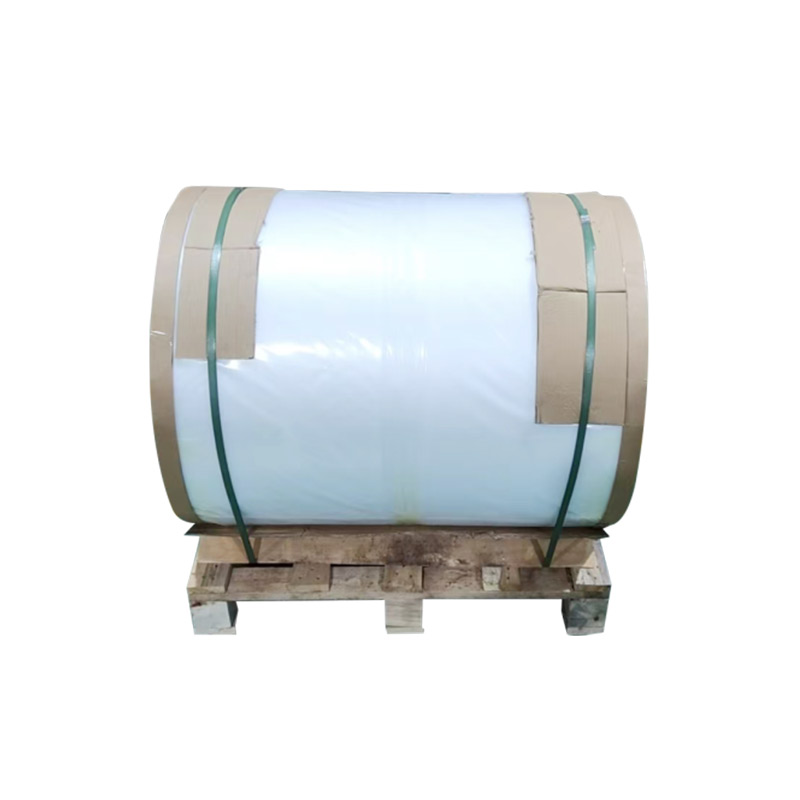

Stretch hood film is a highly elastic, tubular polyethylene film used to cover palletized loads by stretching and then releasing the film to tightly conform around the load. Unlike traditional stretch wrap or shrink film, stretch hooding doesn't require heat, making it energy-efficient and safer for industrial applications.

The film is applied using automatic stretch hood machines, which place and stretch the hood over a pallet, allowing it to contract and firmly secure the load beneath.

Key Benefits of Stretch Hood Film in Pallet Packaging

-

Superior Load Stability

The film’s elastic recovery ensures a tight fit, preventing load shifting during transportation and reducing product damage. -

Enhanced Weather Protection

Stretch hood film is waterproof, UV-resistant, and dustproof, providing full five-sided protection—ideal for outdoor storage or long-haul logistics. -

High Transparency for Branding and Scanning

The film’s clarity allows for easy barcode scanning and visibility of product branding, simplifying warehouse operations and improving inventory accuracy. -

Cost and Energy Efficiency

Compared to shrink film systems that require heat tunnels, stretch hooding is more energy-efficient and faster, cutting down on utility costs and packaging time. -

Environmentally Friendly

Stretch hood film typically uses less material than traditional wraps and is 100% recyclable, supporting eco-conscious packaging strategies.

Why Choose Dostar Packing Equipment Co., Ltd for Stretch Hood Solutions?

Dostar Packing Equipment Co., Ltd is a high-tech enterprise specializing in the R&D, integration, manufacturing, and service of automated packaging lines. With a deep commitment to innovation and customer-centric solutions, Dostar provides both semi-automatic and fully automatic packaging systems, including state-of-the-art stretch hood machines.

By seamlessly integrating stretch hood film technology into automated production lines, Dostar helps businesses:

-

Increase packaging speed and throughput

-

Improve pallet load integrity and appearance

-

Lower labor and operational costs

-

Customize packaging systems based on product size, weight, and shipping requirements

From material selection to complete system implementation, Dostar offers end-to-end technical support and engineering expertise to ensure clients get the most from their packaging investment.

Conclusion

Stretch hood film is not just a packaging material—it’s a game-changing solution for modern logistics and supply chains. Its ability to combine performance, protection, and sustainability makes it the ideal choice for companies seeking to optimize pallet packaging.

With cutting-edge automation capabilities and a strong focus on customer success, Dostar Packing Equipment Co., Ltd is empowering businesses to embrace the future of pallet packaging—efficiently, securely, and intelligently.

Looking to upgrade your packaging system with stretch hood film technology? Contact Dostar today for a customized solution tailored to your production line.

www.dostar-pack.com

Dostar Packing Equipment (Wuxi) Co., Ltd